Departments and Staff

- DYEHOUSE

- WARPING DEPARTMENT, which is composed of two latest-generation automatic warping machines

- WEAVING DEPARTMENT, which is composed of both dobby and jacquard looms, but also of machines for both circular and straight knitting

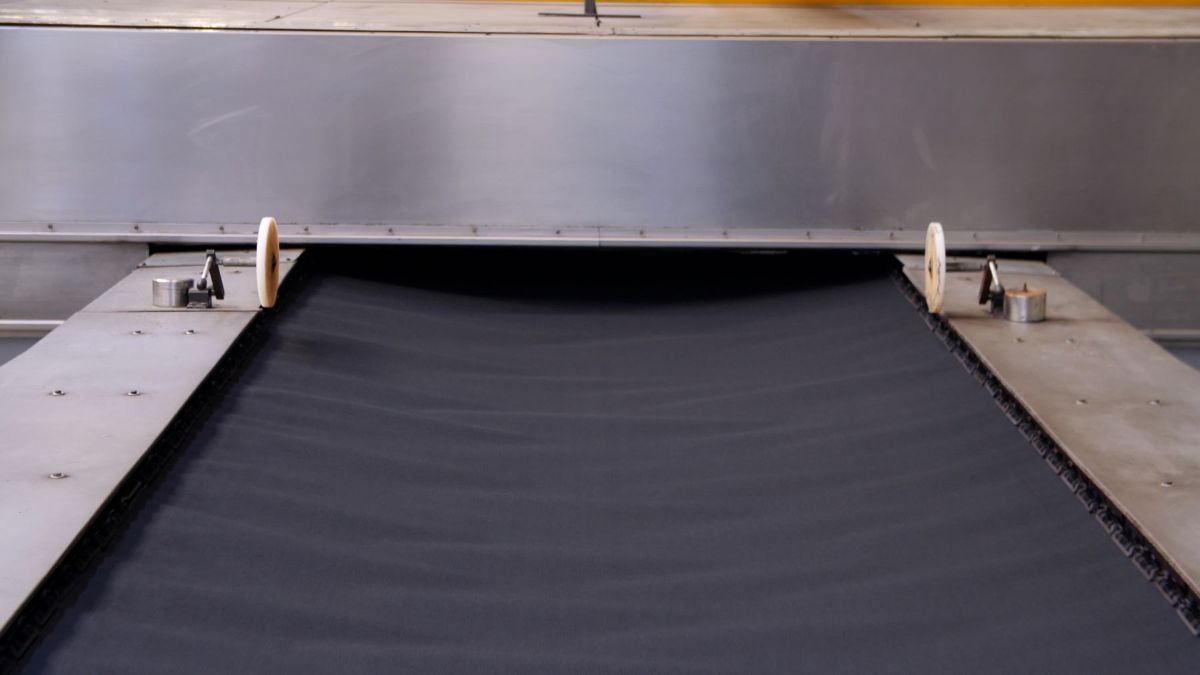

- FINISHING DEPARTMENT, which is able to finish our fabrics with many different processing treatments, such as water and oil repellent treatments, resin coatings but also flame-retardant treatments

- LAMINATION DEPARTMENT

- ELECTRO WELDING DEPARTMENT

- THERMOFORMING and EMBOSSING DEPARTMENT

- CUTTING and SEWING DEPARTMENT

Production departments

R&D DEPARTMENT

Our internal Research and Development department is formed by a team of experts and dedicated people who work every day in order to achieve the best solutions and be able to always find the best materials and technologies to apply in the creation of our beautiful and unique fabrics.

We have a latest-generation CAD that allows our specialists to study and internally develop the FIDIVI collection, but also to create special projects and customised articles, according to our customers’ needs.

The people who work in this department are experts for all that concerns yarns, materials, colour schemes, structures and finishes, and that’s why FIDIVI’s fabrics always distinguish themselves for their quality and performance.

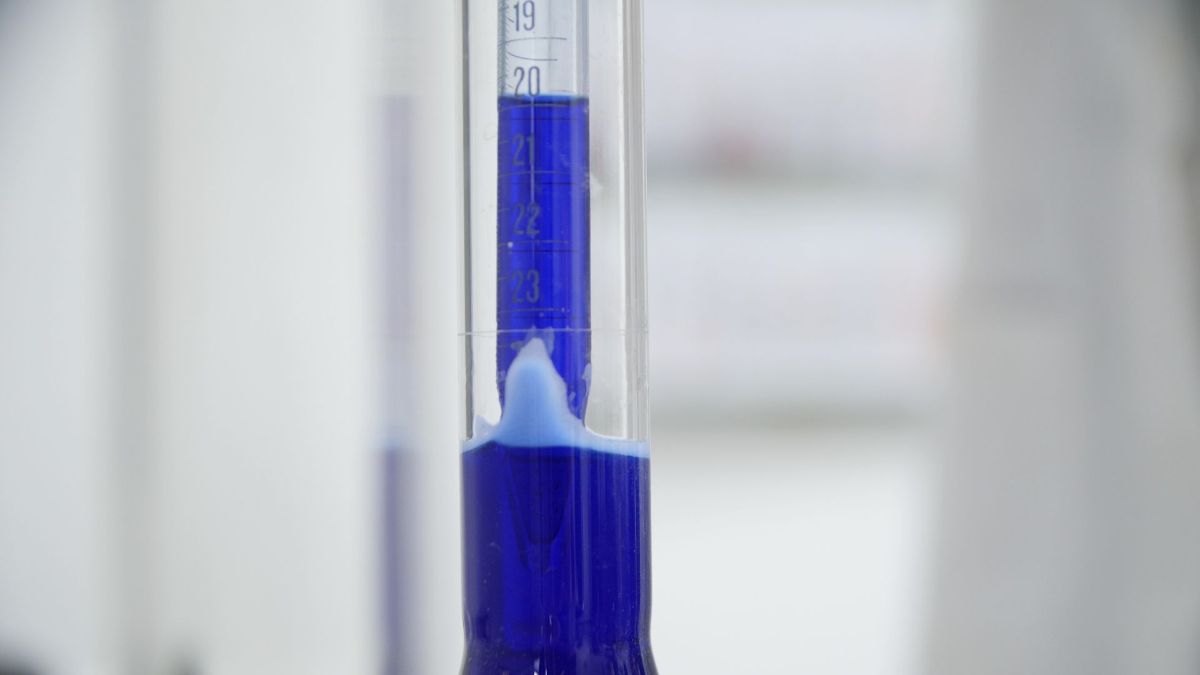

DYEING

Our internal dyeing department allows us to internally dye our yarns, giving flexibility and promptness to our lead times and also giving us the possibility of developing special colours for the customers that may need them.

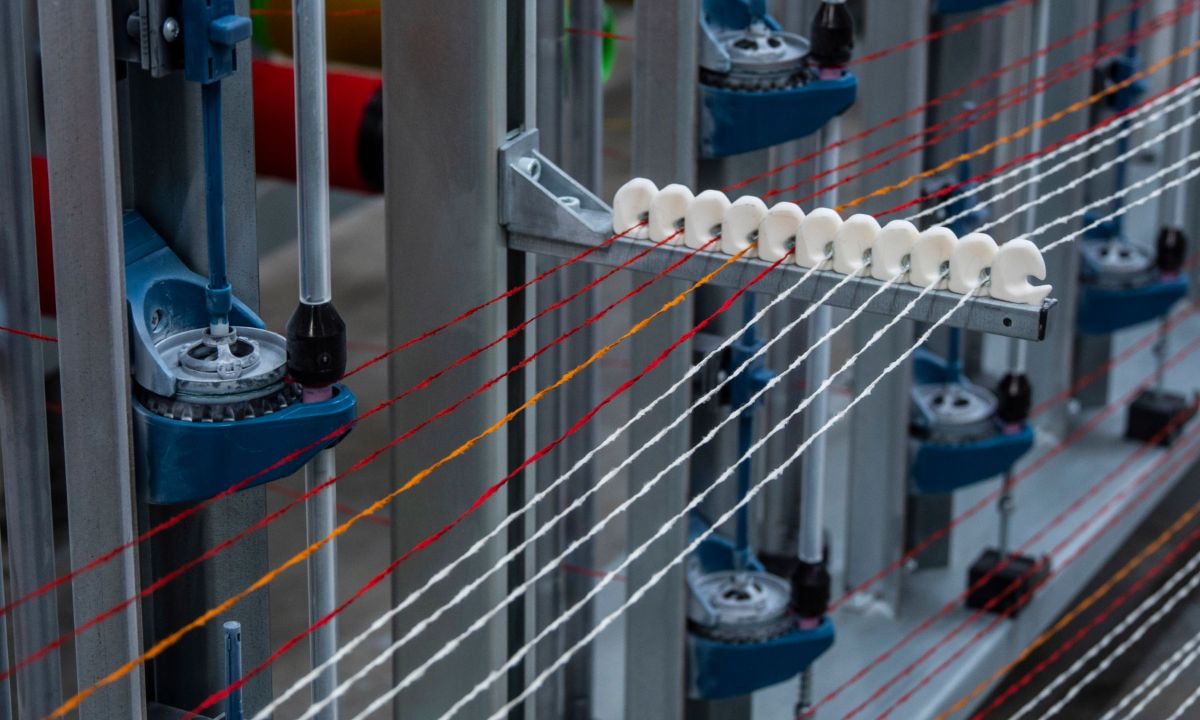

WARPING

Within this department we have two latest-generation automatic warping machines.

We produce our warps daily, according to the needs of our production planning and in this way, we are able to ship our fabrics on time and efficiently.

We are also able to produce special warps for samples or also smaller warps devoted to particular productions based on customers’ specific requests.

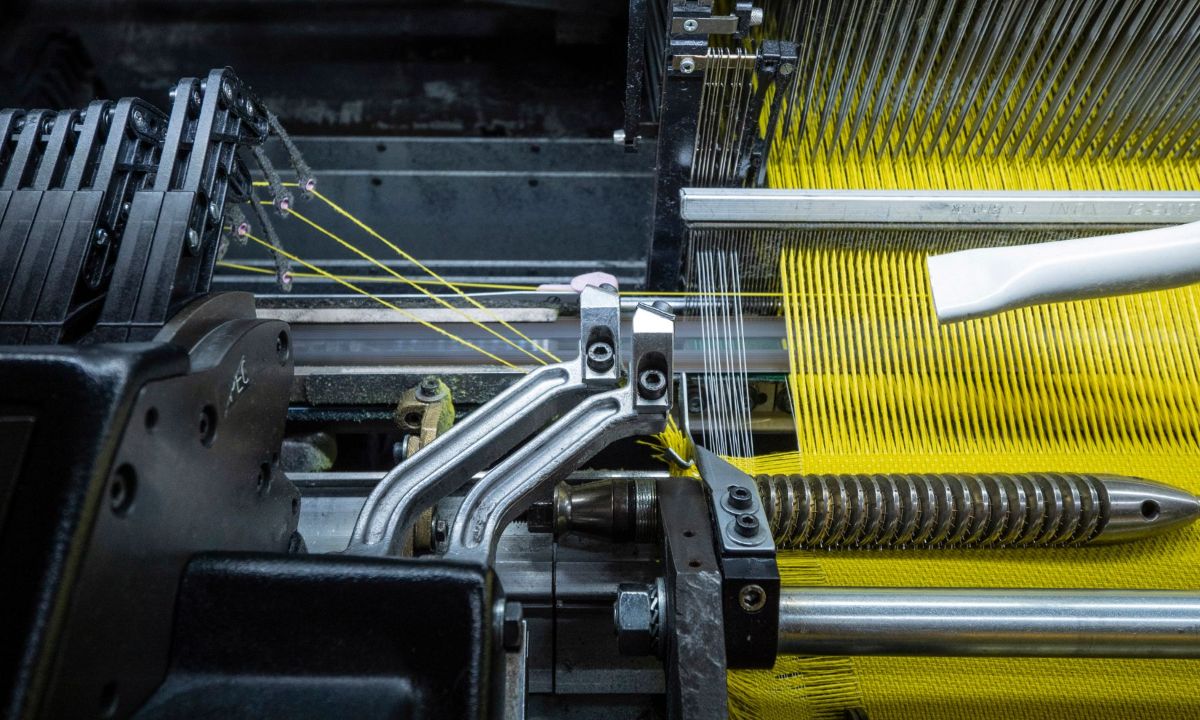

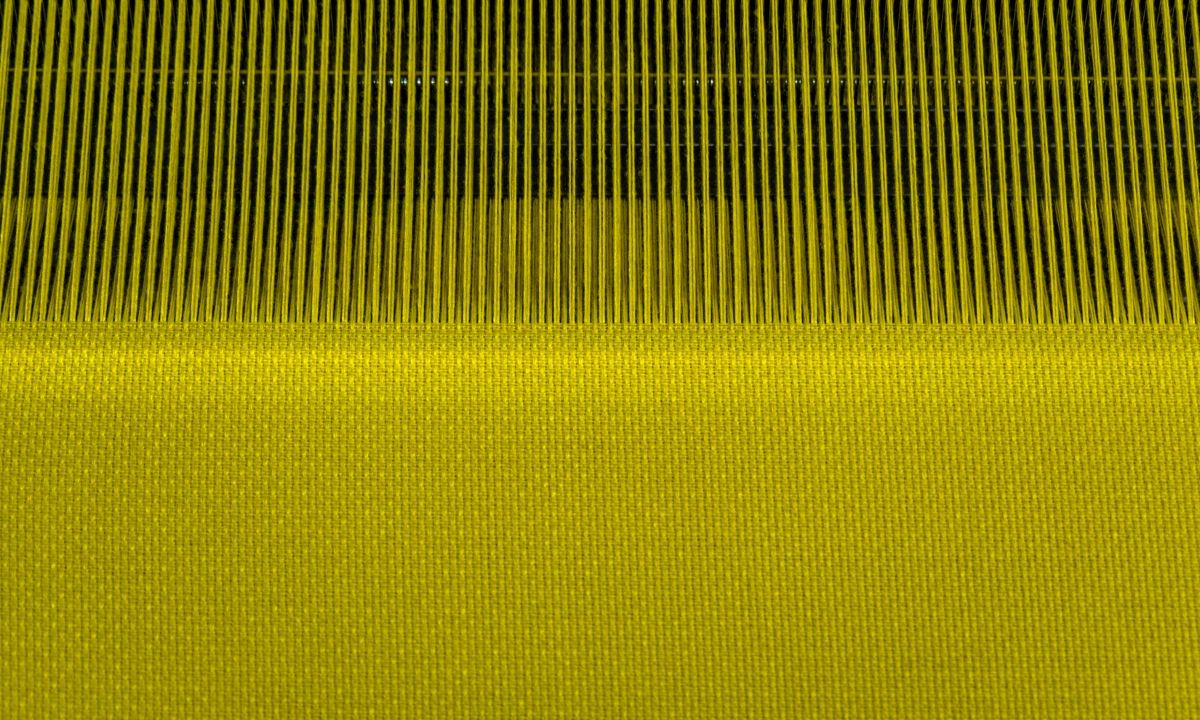

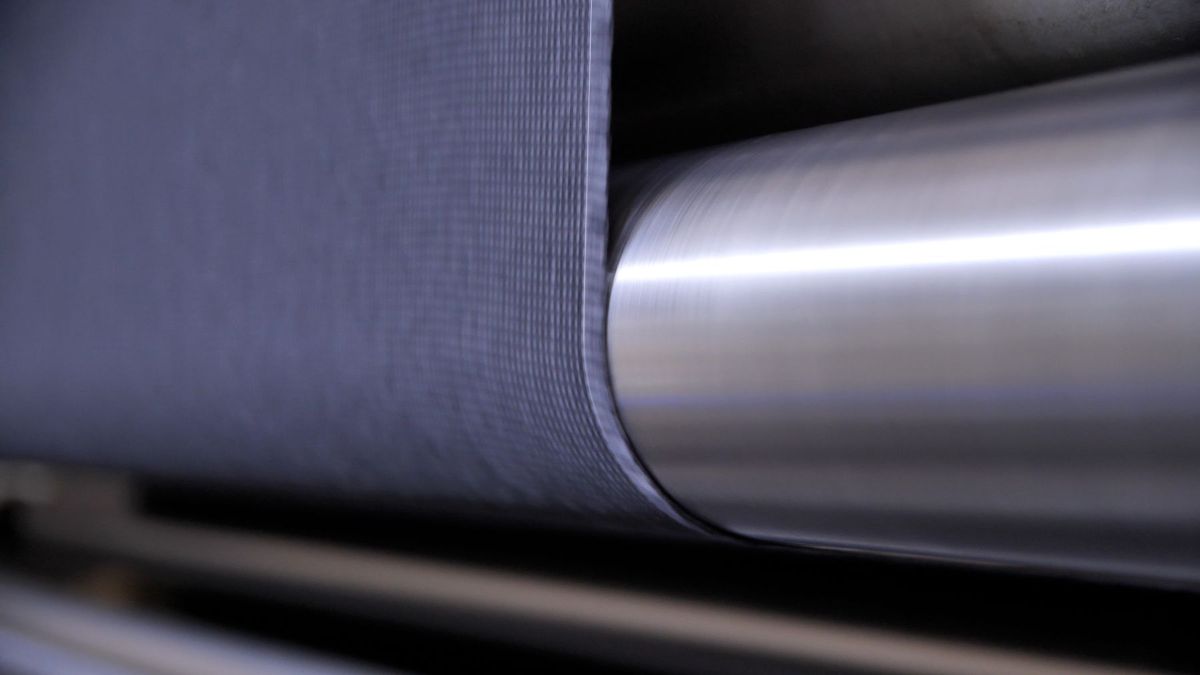

WEAVING

Our weaving department consists of 28 looms, 14 of which are dobby looms and the other 14 jacquards.

We have both single and double height looms.

We also have straight and circular knitting machines; in this way, we are able to complete the range of products that we can offer and include in our collection.

FINISHING

Our internal finishing department is equipped with all the machines that we need in order to finish our products and deliver them, ready for their use, to our customers.

We are able to offer many finishing processes, but the ones that we usually perform are: washing processes, thermoforming processes, stain-resistant processes, water-repellent treatments, calandering processes.

ROLLING

Every day, FIDIVI subjects its articles to various checks, because quality and reliability are fundamental to us.

In this regard, we always perform a double check on each one of our articles.

The first takes place when the article is still on the loom.

The second is the most accurate one, and takes place right before the final packaging, when each metre of fabric is checked by a dedicated professional.

WAREHOUSE

Our internal warehouse offers us the possibility of always being flexible and ready for every shipment.

For each article that we have in our collection, in fact, we guarantee a minimum quantity of metres stocked, reason for which we are always ready to guarantee a cutting service.

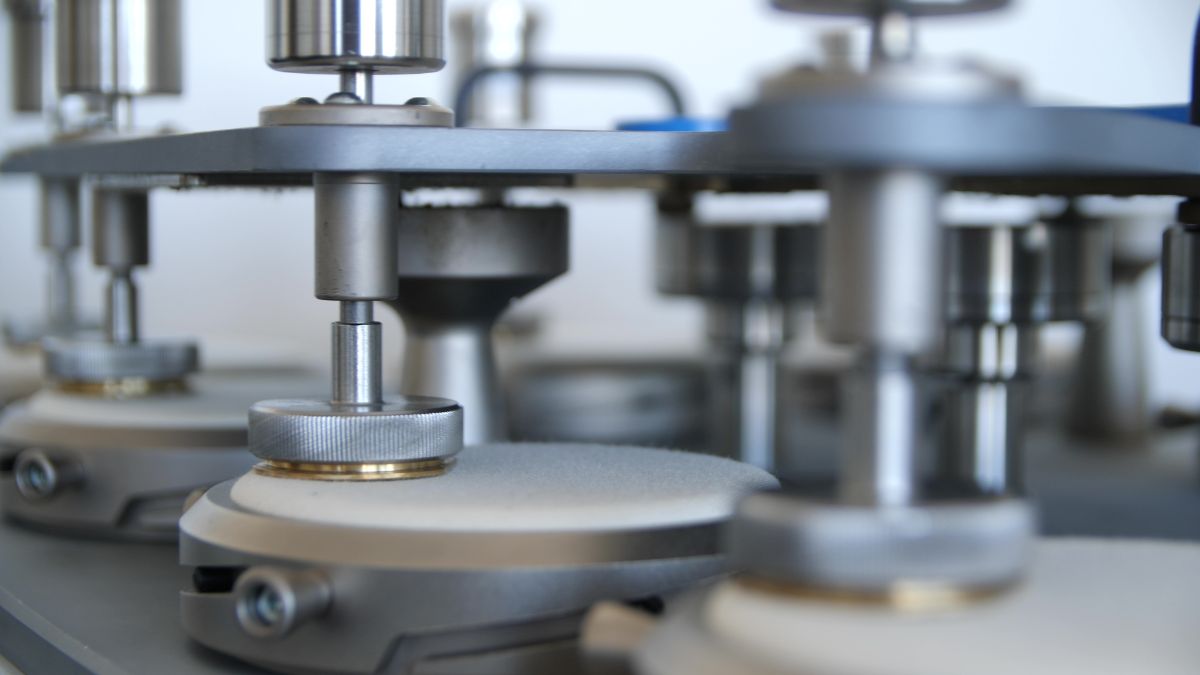

QUALITY INSPECTIONS

Our internal laboratory is a crucial step for every single article we manufacture.

Here, we perform all the technical tests such as traction resistance, martindale but also colour tests made using the spectrophotometer, all of which allow us to check the quality of the result obtained during the dyeing process.

Another test that we are able to do is the fire resistance test. Since we are involved in sectors in which fire resistance is fundamental, we are equipped with a fire chamber that makes us understand the performance that our products offer in terms of fire resistance.

Showroom

In our production plant, we have two showrooms where all our collections are exhibited and where it’s possible to appreciate all of our articles, as well as fabrics that are no longer in the collection, but that have marked the history of our textile company.

Come and visit us to discover our various proposals in terms of fabrics, but also some of the creations from a number of important architects and interior designers, made with FIDIVI textiles!